When a fire breaks out in a residential building, it can spread rapidly. To preserve the structure of the building and, more importantly, save lives, smoke ventilation systems are integrated into the building. Smoke control features, like mechanical smoke ventilation systems, are incorporated in the design phase. Here’s a look at how these systems function, their impact on building design, and the ideal time to involve a specialist in the process.

The Crucial Role of Smoke Extraction

The primary function of a Mechanical Smoke Ventilation System is to manage smoke, facilitate the safe evacuation of occupants, improve visibility, and ensure fire services have proper access to the building. This system typically includes a mechanical extract shaft that serves communal areas such as corridors or lobbies.

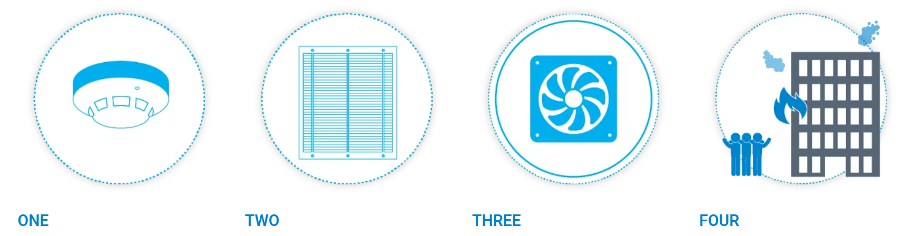

When smoke is detected in a protected lobby:

- The fire damper in the smoke shaft on the fire floor

will open while all other dampers remain closed. - Simultaneously, the vent at the top of the staircase

opens to provide fresh air to the smoke extraction system. - A fan at the top of the shaft extracts the smoke,

preventing it from spreading to adjacent compartments.

Why It’s Essential to Consider Smoke Ventilation Early in the Design

Architects often aim to go beyond the basic industry standards, exploring innovative fire safety solutions. However, achieving optimal smoke control while meeting spatial, aesthetic, and budgetary constraints can be a complex challenge that often needs compromise on aesthetics.

Prevents Over-Specification Without Compromising Safety

Involving experienced fire engineers and designers from the outset helps ensure the correct smoke ventilation system or combination of systems is selected. This allows for a tailored solution that exceeds standard code-based requirements while meeting design goals. Early collaboration can also help reduce project costs and avoid over-specification, all while ensuring full compliance with safety regulations.

In addition to system selection, considerations such as the system’s location, minimising long-term maintenance costs, and maximising saleable floor space can all enhance the overall value of the development.

Computational Fluid Dynamics (CFD) modelling is a crucial tool used by fire engineers to justify complex designs for building control approval. By simulating and analysing fluid dynamics (liquids and gases) through computational methods, CFD modelling provides valuable insights into flow behaviour, pressure distribution, and heat transfer within a given system or design. The results of this analysis support the system’s design, offering detailed evidence for building control approval. Beyond regulatory compliance, CFD modelling also delivers a range of additional benefits.

Minimising Design Changes During Construction

Addressing smoke ventilation design early also reduces the risk of costly design modifications and delays during construction. By ensuring a detailed and approved System Design at an early stage, potential issues can be identified and resolved before installation begins. This proactive approach not only streamlines the approval process with building control but also ensures there are no issues during the Smoke Ventilation System Installation, knowing that it meets the required performance and operational standards. Furthermore, early planning minimises coordination conflicts with other trades, reducing the likelihood of expensive reworks and project disruptions. Ultimately, this results in a more efficient construction timeline and cost savings for developers and contractors alike.

Engaging with smoke ventilation specialists and fire engineers early can greatly enhance the design process and support Building Safety Regulator (BSR) approval for Planning Gateway 2 (PG2).

Early involvement ensures the smoke ventilation strategy complies with the latest fire safety regulations, such as Approved Document B, BS 9991, and BS 9999, reducing the risk of late-stage revisions that could lead to delays and increased costs.

Learn More about Smoke Ventilation Design

How MSVS Impacts Building Design

As cities grow more densely populated and developers opt to build upwards, the need for efficient mechanical smoke ventilation systems becomes even more crucial. Mechanical smoke ventilation is generally required in buildings exceeding a certain height, typically around 30 metres, where natural ventilation is no longer sufficient to clear smoke effectively. Longer travel distances also make a more controlled system necessary. However, specific regulations and building codes vary by jurisdiction and design, with factors such as travel distance and layout also influencing the need for mechanical ventilation.

- Enhanced Performance for Evacuation Routes

As per the limits set out in The Building Regulations Approved Document B (ADB), where travel distances exceed 7.5m in an un-sprinklered building and over 15m in a sprinklered building, MSVS provides superior smoke clearance compared to natural ventilation systems, improving escape routes. - Enables Smaller Smoke Shafts

Due to their increased efficiency, MSVS systems allow for the use of smaller smoke shafts, with dimensions as small as 0.5m² or 0.6m², compared to the 1.5m² required for natural systems. - Greater Design Flexibility

The improved efficiency of MSVS justifies larger compartment sizes and extended travel distances within common corridors, providing more flexibility for the building’s design. - Significant Space-Saving Potential

Early integration of MSVS can create substantial space savings. For example, in residential buildings taller than 11m, ADB stipulates maximum travel distances for escape routes. By adopting an engineered approach with MSVS, it may be possible to reduce the number of required escape routes, such as eliminating a second staircase, thus freeing up valuable floor space.

Multiple Benefits of MSVS

While the initial investment in MSVS is higher than that of natural systems, its components can be used with other systems, such as corridor environmental systems, that take advantage of the smoke shaft and dampers. This integration helps cut costs by reducing the need for costly air conditioning units, which can be particularly beneficial in densely packed urban areas.

£3.5 Million saved

through space efficiency

Increased Value Through Space Efficiency

Value engineering through the intelligent specification of MSVS can also lead to significant savings. For instance, in the Dalston Lane South project, FDS’s involvement saved Barratt East London £3.5 million by reducing the number of stair cores and smoke shafts needed, maximising space within the building.

Conclusion

Incorporating a mechanical smoke ventilation system into the early stages of building design offers numerous benefits, from enhanced fire safety to increased space efficiency.

To ensure the system’s success, it’s crucial to engage a specialist who can provide a comprehensive service covering design, supply, installation, commissioning, and ongoing maintenance. By doing so, developers can ensure a safer, more efficient, and cost-effective building project.

For more information, contact FDS Contracting today!